AT A GLANCE

Challenge

Siemens sought to improve training deliverables to help overcome a growing skills gap.

Solution

Siemens partnered with BILT to provide a portable training platform for distributors and contractors—whether they’re upskilling in-house or onsite.

Outcome

Distributors increased operational efficiency which led to faster fulfillment and higher sales. BILT also enabled contractor speed and efficiency.

Making Knowledge More Portable

Increasing Efficiency for Distributors

Over the past few years, the Covid-19 pandemic wreaked havoc on the global supply chain. Distributors who already faced longer lead times on fully assembled goods needed to find a faster, cheaper way to get products to their customers.

Siemens responded to this need by providing distributors with multiple components instead of fully assembled products. Distributors then put everything together according to customers’ varying needs. “As a distributor, there’s a huge value here because there is the potential to receive the product much quicker,” says Quatela.

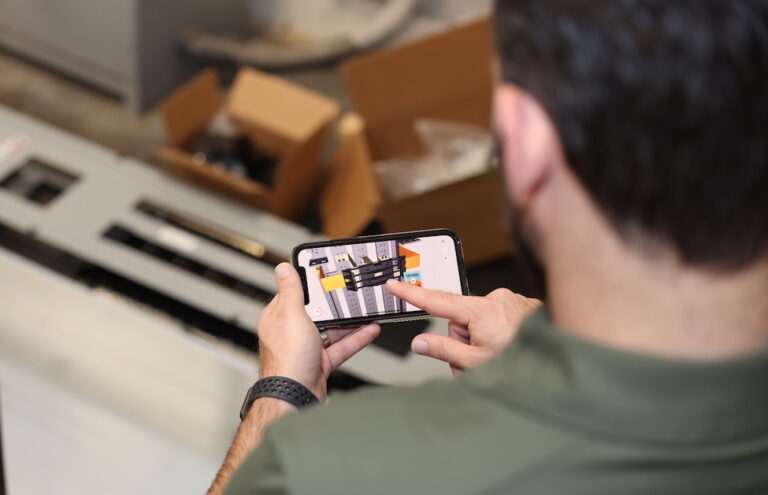

Siemens sought to provide a standardized method for distributors to assemble the components. “We created a 3D experience with BILT to help distributors put together the product as a value-added service,” says Quatela. “Distributors are always looking for ways to differentiate themselves in the marketplace. This is a great way to do that.”

Boosting Distributor Success with Digital Innovation

Changing the Game for Contractors

Last year, Siemens was a sponsor at the IDEAL National Championship, which featured teams of electricians competing in timed installations. Apprentices partnered with master electricians to compete in the final event. The contest was to install the P5 Power Panel—the largest footprint distribution panel in the Siemens family. They provided each team an iPad with 3D instructions powered by the BILT app instead of traditional paper instructions.

In the pre-contest briefing, one of the pros, Roman Ryszewski of Pennsylvania, strongly objected to using an app for the installation. He is a seasoned contractor and competitor who won the 2017 professional title.

“I’d never used [BILT]. I usually go by the paper instructions or figure it out,” says Ryszewski. But after he began, he realized quickly that something was not right. “So, I turned [BILT] on and in the very first step I could rotate the image to the side view and understand how to put the parts together. Actually, the app was very helpful.”

“For him to need the app, with all his experience, it proves it’s obviously really helpful for when you’re just starting out,” says teammate Brady Wraalstad, a third-year apprentice from Wisconsin. “Everyone could navigate the app with ease, not just those of us who grew up with an iPad in our hands. The 3D modeling features are pretty cool, especially if it’s your first time or if you haven’t mastered the procedure yet.”

“The potential is limitless,” says pro competitor Alec Perkins, a journeyman from Iowa whose team placed second. “It’s unbelievable content. What you’re doing for the industry—especially for future generations of electricians—is paramount for the transfer of knowledge.”

“Hearing that validated everything Siemens and BILT are trying to achieve. And that is to move the industry forward. It’s about an evolution—actually, a revolution—that’s going to change the game,” says Quatela.

Investing in the Next Generation of Electricians

The next generation of electricians is made of digital natives who grew up gaming and are accustomed to instant access to information. Rather than learning through textbooks or in-person instruction, this generation prefers the flexibility to process information through digital 3D images.

“BILT is absolutely the next step in the evolution of training,” says Lab Instructor Christie Peterson of the San Francisco Joint Apprenticeship & Training Committee for Local 6. She was one of the judges at the IDEAL Championships. Peterson says BILT’s adaptability and interactivity is ideal for apprentices.

“It’s clean. It’s clear. It’s good,” says Peterson. “Sometimes paper instructions are a blurry copy of a copy. BILT gives them the upper hand.” She says electricians in training may not see some products in the field for a year or more, but if they had the opportunity to manipulate 3D animations in the classroom, then when they finally see them in the field, it will be easy for them to be successful.

“It’s possible trainees could install products without ever having touched the equipment in the classroom if they have familiarized themselves with the 3D instructions,” says Peterson. She thinks it’s “the next best thing” to a hands-on experience.

“Everything our team tries to build is centered on teaching,” says Quatela. “Sure, there’s always a motivation for greater sales, revenue, and profitability. But if we can make that electrician smarter, safer, and more employable—whether it’s someone with 40 years of experience or a year-one apprentice—then we’re doing our job.”

“Safer in terms of installation? Yes. Faster? I think BILT’s definitely going to increase productivity,” says Peterson. “The app helps you think ahead and plan for all the materials and tools you need for the job instead of making multiple trips.”

Siemens & BILT: The Hub of Continuous Learning

Looking ahead, Quatela says Siemens must listen to the individual needs of their customers and distributors and continue creating innovative content to remain a leader in this space.

“With BILT, we’re just scratching the surface,” says Quatela. “We have many other products on our roadmap including getting BILT-based training into our manufacturing plants. Siemens is investing in this space to make both employees and customers smarter, safer, and more confident that they’re doing things right.”

Great experience

mspencer

After assembling the P5 Power Panel, 5 stars

Wonderful and innovative

bmiller

After reviewing the Commissioning Standards, 5 stars

Dual voltage panel that will work for almost any application!

RManning

After assembling the P5 Power Panel, 5 stars

Amazing

thanks

After assembling the Strap & Breaker Kit, 5 stars