Digital work instruction software is an intuitive and adaptable solution that simplifies and accelerates the learning process for your employees. It brings together visual aids, audio, text, and interactive or immersive experiences. In today’s industrial landscape, visual work instructions offer far more benefits than traditional work instruction methods like paper manuals.

Many companies in the industrial space are an ideal fit for digital work instructions because they meet these criteria:

- Geographically distributed workforce

- Complex but consistent processes

- High volume of headcount turnover and/or growth

- Loss of institutional knowledge from an aging workforce or “silver tsunami”

- Digitally native workforce

This article highlights specific industries that have these defining characteristics and can’t afford to miss out on digital work instructions.

1. Manufacturing

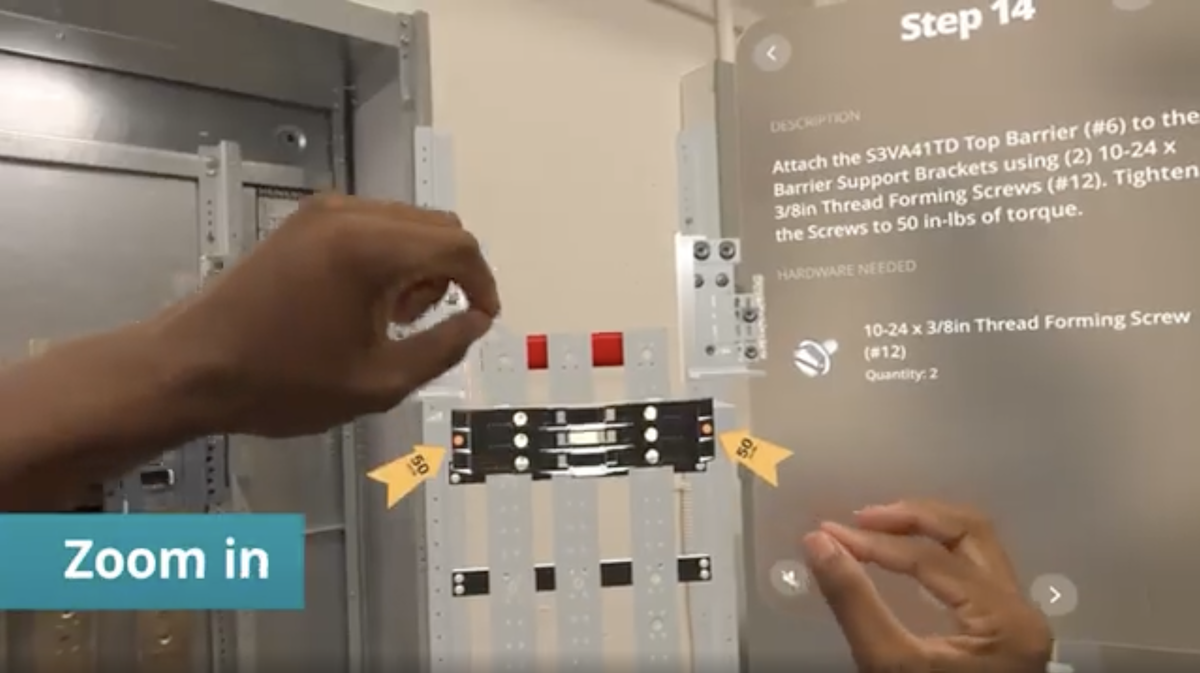

Manufacturing processes are intricate and require extreme precision. For example, an error in automotive assembly can create a safety risk or require extensive rework. Digital instructions can streamline these processes and improve quality control because they provide detailed information and allow for visual aids or immersive experiences. According to a recent survey of manufacturers, 59% of the 179 respondents who were not yet using extended reality (XR) in their training and instructions plan to begin using it within the next five years.

Digital work instruction software for manufacturing also provides real-time updates, which is critical in an industry where standards and processes often evolve. If you make a change to a set of instructions, your employees will instantly see the new version. This helps reduce errors, increases efficiency, and ensures your team uses the most up-to-date and effective strategies in their work.

2. Energy and Infrastructure

Managing large-scale electrical and infrastructure projects often involves providing multiple teams and contractors with clear and standardized instructions. Digital work instructions software can standardize instructions across project sites so contractors and employees know exactly what steps no matter where they’re working on a given day. This not only reduces errors but also improves safety.

Along with digital instructions, XR is emerging in the electrical industry. It offers great value for operations and maintenance, where accuracy is essential to a project’s success. Enhancing electrical distribution monitoring and alarming is a key focus because it helps employees isolate risks and restore power more quickly.

3. Oil and Gas

Working in the oil and gas industry is inherently high risk due to the threat of fires, explosions, and chemical exposure. Employees have to follow safety procedures to protect themselves and others, and digital work instruction software helps ensure that they work carefully and accurately in drilling and refining operations.

Oil and gas companies can use instructions with immersive technology to create training experiences that allow employees to practice dangerous tasks in safe environments. They can also support frontline workers, giving them access to support and information when they face issues in the field. An employee who is dealing with a delicate or potentially hazardous task can use XR and 3D work instructions to see exactly what steps they need to take.

Oil and gas workers can also use XR to connect remotely with off-site experts. This enhances their safety and reduces the company’s carbon footprint. With the International Energy Agency reporting that the oil and gas industry is responsible for almost 15% of energy-related greenhouse gas emissions, companies are under increasing pressure to minimize their environmental impact.

4. Construction

Field service and construction work are dynamic and varied fields where employees frequently move between sites, often visiting multiple locations in a single day. It’s impractical and inconvenient for them to carry printed manuals, but they still need reliable access to work instructions.

Using paperless work instructions allows these workers to get guidance regardless of where they are. Instructions with XR technology also facilitate better decision-making by identifying potential challenges, optimizing designs, and promoting project success from the outset.

In addition, these types of instructions can enhance safety by providing immersive training simulations and real-time hazard identification. They teach people how to use complex equipment or heavy machinery without using the actual equipment, eliminating the risk of damage or costly repairs and reducing errors moving forward.

In an industry where accuracy is a top priority, the fact that digital work instruction software provides real-time updates to field technicians is another asset. It gives employees the latest instructions and information so they don’t accidentally use an outdated procedure that no longer complies with standards or government regulations.

5. Aerospace and Aviation

The aerospace and aviation industry is strictly regulated—and for good reason. Even a small error could pose a significant safety threat, so accurate and compliant work instructions are crucial.

Using interactive work instructions in maintenance, repair, and overhaul (MRO) operations increases the chances that employees will perform procedures correctly. Instructions enhanced with augmented reality (AR) allow maintenance personnel to visualize and interact with 3D models of aircraft components. This provides them with a deeper understanding of complex systems and supports more efficient and precise repair procedures.

Digital work instruction software is equally beneficial in training. Upcoming aerospace technicians and existing workers who want to upskill can learn about new aircraft models and technologies with immersive instructions. This is especially useful in pilot training, where it can be difficult to give trainees and employees hands-on access to emerging technologies.

Digitize Your Work Instruction Software With BILT

For some industries, digital instructions aren’t just innovative and exciting; they’re also key to improving safety, achieving greater quality, and working more efficiently. When your organization decides it’s time to make the switch to digital work instruction software, BILT is ready to help.

BILT offers turnkey 3D interactive instructions for mobile devices and 3D immersive instructions for training on Apple Vision Pro. Your employees can download their instructions for use without WiFi using our iOS, visionOS, or Android apps, which are available worldwide in 12 languages.

Request a demo to learn more about how BILT’s digital work instruction software personalizes the user experience, reduces cognitive load, and promotes more consistent employee performance.