Spatial computing may not be a household term yet, but it is taking hold in workplace environments. That’s because spatial computing technology is redefining job training and work instruction software, particularly in the manufacturing, electrical, and aerospace industries.

Why would businesses want to incorporate spatial computing into their work instruction software? The answer varies but ultimately comes down to improved learning experiences and enhanced outcomes. The future of spatial computing is tied directly to digital work instructions and the potential for greater productivity, efficiency, and safety.

Role of Spatial Computing in Work Instruction Software

Spatial computing is a broad term encompassing different technologies and capabilities. Two of the most popular extended reality technologies under this umbrella are augmented reality (AR) and virtual reality (VR). AR refers specifically to overlaying digital content on physical environments, while VR refers to an immersive simulation that blocks out the real world. Spatial computing combines elements of AR and VR with additional devices to create interactive, context-aware experiences.

How Spatial Computing Improves Digital Work Instructions

By gathering and analyzing data using multiple kinds of sensors, spatial computing technology can seamlessly intertwine the physical world and digital world. This allows for greater interaction that goes beyond the capabilities of traditional AR and VR technologies and produces more realistic training for work instruction software.

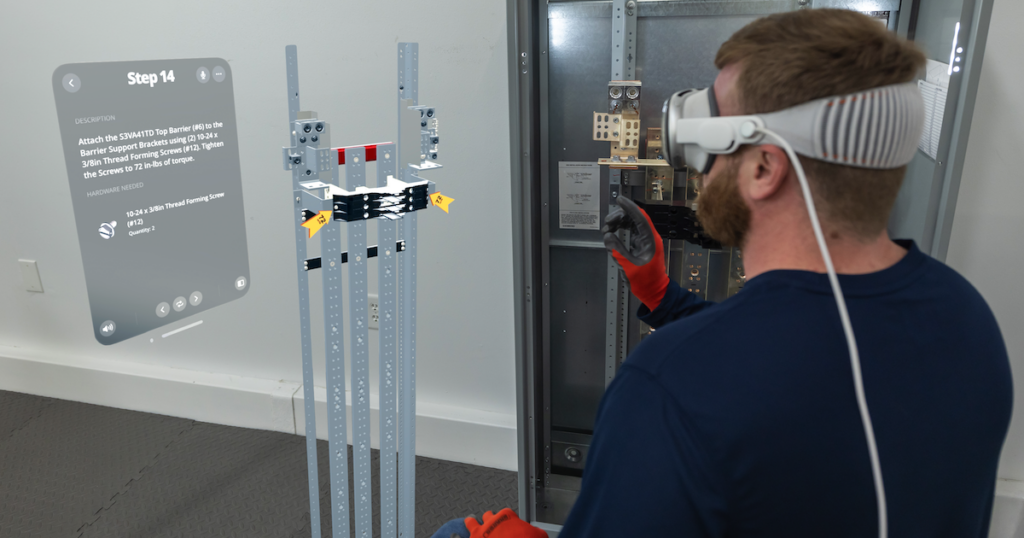

People often interact with spatial computing applications through VR headsets or mixed reality (MR) devices like the Apple Vision Pro. For example, if an organization uses 3D work instruction for field operations, trainees and employees can use spatial mapping with their Apple Vision Pro computers to overlay instructions on their physical surroundings and put a digital version of the object involved in their task side-by-side with the physical object. That way, employees can see exactly what they need to do as they’re doing it.

RELATED: Buyer’s Guide to Technical Training

Applications of Spatial Computing in Various Industries

Many industries have already incorporated spatial computing into their training programs. Some of the fields that have seen the greatest advantages from this approach include:

- Manufacturing: Spatial computing can remotely assist workers and display virtual work instructions, allowing workers to assemble parts and perform maintenance tasks with improved quality assurance and efficiency.

- Electrical: Companies like Siemens now offer electrical training with spatial computing because it allows apprentices and electricians to learn industry practices more safely without sacrificing accuracy.

- Aerospace: Another popular spatial computing application is aviation training, which improves flight safety and opens avenues for more flexible training opportunities.

With digital work instructions and spatial computing, employees can strengthen their core skills and expand their skill sets, ultimately making them more positive contributors to their companies.

Spatial Computing Advantages for Digital Work Instructions

If you’re unsure whether spatial computing is a worthwhile investment, consider these specific ways it can improve your work instruction software.

Enhanced Training and Onboarding Processes

Spatial computing can streamline training and make onboarding more efficient when bringing on new employees. This immersive technology also makes training more flexible because workers spend less time physically training in the field. As a result, they can get up to speed on accepted practices and strategies more quickly.

Interactive Learning Experiences

Learning and practicing a task in an immersive environment helps workers develop spatial awareness and muscle memory, both of which contribute to improved skill retention. By actually building a product rather than reading about it or watching someone else build it, employees gain a deeper understanding of the process and can apply it more effectively in real-life situations.

Improved Task Execution and Efficiency

Providing employees with raw materials or equipment is essential to hands-on learning and industrial training, but those resources are often limited. Workers who can complete these training tasks with spatial computing gain the same benefits as practicing with physical objects. This boosts motivation and productivity while reducing the risk of breaking expensive equipment or creating a safety hazard on the job.

Real-Time Guidance and Feedback

When employees encounter a problem out in the field, you might try to talk them through a solution over the phone or tell them to wait until you can get someone on-site to support them, but both of those scenarios are less than ideal. With spatial computing, you can provide live support for tasks, offering insights on how to accurately perform them in the moment, regardless of your location. This saves time, prevents unnecessary delays, and helps minimize errors.

Hurdles of Training with Spatial Computing in the Workplace

Enhancing your workplace training with spatial computing offers a wide range of benefits, but it also creates a few challenges. Combining spatial computing technology with your existing work instruction software might be challenging, particularly if you use an older system with limited integration options.

In addition, future developments and innovations, such as artificial intelligence, could affect efficiency in manufacturing environments. Anticipating those advances helps you stay on top of the state of spatial computing and work instruction technology to ensure that you’re offering the best possible experience for your employees.

Embracing Spatial Computing with BILT

By incorporating spatial computing solutions into their work instruction processes, field operations companies can enable their employees to interact and communicate with each other and machines in new ways. Expanding virtual reality and augmented reality into the real world leads to improved accuracy, safety, and productivity, and these advantages will only increase as the technology continues to grow.

If you’re ready to bring your work instruction software into the modern age, BILT can help. BILT focuses on 3D interactive instructions to guide work on mobile devices and digital work instructions for industrial training programs on Apple Vision Pro.

With BILT, you’ll have access to insights, analytics, and real-time user feedback to inform your product and operations leaders. Request a demo today to see how guided work instruction software can benefit your employees.